Features & Benefits

• Digital modules (output/input/mix), analog modules (output/input/mix), temperature measurement modules, network modules, remote I/O communication modules, motion control modules

Specifications

• Digital modules (output/input/mix) : 16 , 32 , 64 I/O

• Analog modules (output/input/mix) : 16-bit 4 channel, 6 channel, 8 channel inputs/outputs

• Temperature measurement modules: conversion time 150ms/channel, overall accuracy+/-0.6%(Full Scale), resolution 0.1°C / 0.1°F(24-bit), RTD inputs: PT100, PT1000, Ni100, Ni1000, or • 0~300Ω, thermocouple inputs: J, K, R, S, T, E, N

• Network modules: EtherNet/IP, DeviceNet, PROFIBUS-DP, CANopen and serial communication modules

• Remote I/O communication modules: DeviceNet, PROFIBUS-DP and EtherNet/IP RTU modules

Applications

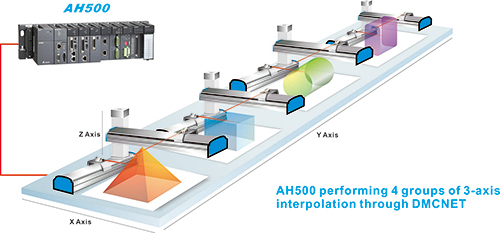

Large Scale Industrial Machines

• The AH500 supports excellent motion control functions including 3-axis linear interpolation, 2-axis arc interpolation, and 3-axis helical interpolation. In addition, the AH500 is capable of controlling up to 12 axes or 4 groups of 3-axis interpolation synchronously at 1ms through Delta’s high speed DMCNET motion control network. The AH500 satisfies requirements for complex processing or precise motion control and is effective for applications such as building material processors, warp knitting machines and food packaging machines.

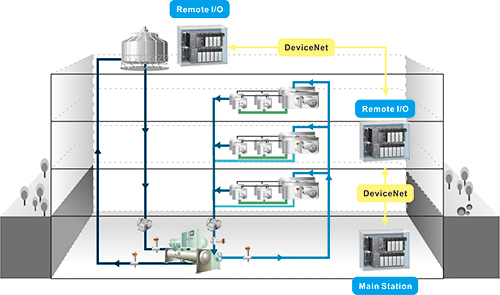

System Applications

• The AH500 is a modular system controller designed for almost all types of high-level automation tasks. Its abundant selection of I/O modules and the flexible system structure provide the best solutions for all kinds of system integration requirements. Through remote I/O expandability, you can build up the AH500 main station as a central control system and allocate the remote I/O systems on different floors for HVAC applications, or in different processing stations for the paper-making industry. The AH500 not only fulfills the application requirements for industrial machines or devices, but it also provides total solutions for automation systems.